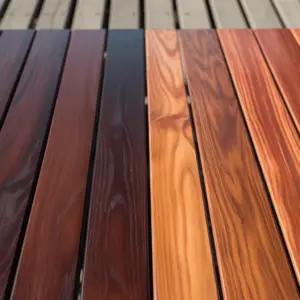

Polyshades and Gel Stain, When it comes to finishing a wood-based construction, your alternatives seem to be on either end of the spectrum: classic varnishes, stain, or a more thorough coating from the color of choice.

In most cases, people tend to weigh between Polyshades and Gel stains. Which is the best option for you? It might be challenging to settle on a single vote, but this article has everything you need to know about Polyshades and gel stains to help you get the best outcome from your project.

As we get started, you need to know that PolyShades makes it simple to modify the color of your wood that has already been stained or polyurethane. To remove the existing finish, no stripping or vigorous sanding is required. Make the surface rough lightly using the fine-grit sandpaper, clean up any sanding dust, then apply a coat of PolyShades.

On the other hand, Gel stain is a happy medium that takes even less time to prepare. It’s similar to most pigment-based conventional stains and may be found alongside them at practically any hardware shop. Minwax and Old Masters are famous gel stain makers.

A thickening ingredient added throughout the production process of gel stain allows for easier application and color concentration. The resultant finish strikes a balance between a translucent stain and an opaque paint, giving some DIYers the best of both worlds even without bother.

Consider gel stain finish for your bare-wood structure or a newly stripped hardwood table. To help you in proper decision-making, we’ve included the most important uses, benefits, and negatives of both Polyshades and Gel stain.

Table of Contents

Polyshades Vs Gel Stain: Overview

Polyshades

Product Details

- Application Tool: Use a high-quality natural bristle brush

- Cleanup: Works best with mineral spirits

- Coats: Typically, two coats of Polyshades are recommended. However, to deepen the color, you can apply the third coat.

- Coverage: Polyshades cover 120-150 sq. ft. per quart

- Dry Time: It takes approximately 6 hours for Polyshades to dry up.

- Location: Mostly used in the interior wood surfaces

- Recoat: Apply the Polyshades recoat after 6 hours

- Recommended Uses: Polyshades are recommended in furniture, cabinets, woodwork, doors, and accessories.

- Sheens: satin and gloss

Uses

PolyShades is made from a stain and polyurethane combination. It brings out the best wood grain by combining a rich stain color with long-lasting polyurethane protection in one simple step. It can also be applied over polyurethane finishes to change the color of your finished wood.

Benefits

PolyShades is a solution that blends stain for vibrant color with polyurethane. It also offers ultimate protection on the item applied. Polyshades are an excellent option for individuals who don’t want to waste time staining with one treatment and then protecting with another.

Since Polyshades has polyurethane, the wood finish is protected from unnecessary stretching. In addition, Polyshades also protect the coat surfaces from water damage.

After applying Polyshades to your wood furniture, it will give a smooth and glossy finish. Your home will look more sophisticated, and in the end, the items with Polyshades coating guarantees life-long durability.

Negatives

Polyshades cannot be used on the floors. Its odor is also sometimes unpleasant to some individuals.

Gel Stain

Product Details

- Application Tool: Use foam applicator brush or a piece of cloth

- Cleanup: Use the mineral spirits

- Coats: 1 coat of gel stain is recommended, but to darken the wood finish color, you can apply the second coat after 8 to 10 hours.

- Coverage: Gel stain cover approximately 200 sq. ft. per quart

- Dry Time: The gel stain takes around 24 hours to dry up.

- Location: Gel stain is used on both interior and exterior surfaces. Notably, it should be top-coated with a clear protective finish.

- Recoat: You can apply the recoat of gel stain after 8 to 10 hours

- Recommended Uses: Gel stain is recommended in woodwork, molding, furniture, doors, trim, cabinets, and accessories.

Uses

Gel Stain was created to offer you complete control over the staining process. It’s expertly designed to help you in achieving remarkable results. The non-drip composition of Gel stain makes it simple to apply to vertical surfaces. It can be used consistently on wood and non-wood surfaces like fiberglass, veneer, and metals.

Benefits

Are you looking for the color and depth that would make the wood so appealing? Of course, it should be something with excellent consistency in grain and character.

Gel stain is the ideal choice for people who can’t decide between staining and painting. Gel stain provides a middle ground between the two aspects of transformation.

Polyshades and Gel Stain name is self-explanatory. The consistency of Gel Stain is gelled. It’s perfect for vertical surfaces because of its non-drip composition. Because it has a thicker body, it stays closer to the wood’s surface, allowing for better color control. Gel Stain may also be used to give non-wood surfaces, such as metal, veneer, and fiberglass, a lovely wood look.

Gel stain gives you a light and gleaming wood finish. Despite the fact that Gel stain looks a lot like the pigment-based stains you’re probably more familiar with, it consistently produces concentrated-yet-transparent color. It’s also simpler to apply gel stain than the usual, watery stuff lacking thickening ingredients.

Since Gel stain only remains on the surface of the wood rather than sinking into the pores, it’s an excellent choice for finishing birch, cherry, maple, and pine, which don’t absorb traditional stain uniformly. Gel stain is very useful when staining a surface that can’t be stretched horizontally—for example, an installed cabinet.

Another significant advantage is that you don’t have to sand and strip wood before putting Gel stains on it. Essentially, this implies you can complete the task faster with far less effort.

Negatives

Gel stains can collect in crevices, dips, and corners. So, if you don’t want a splotchy finish, be sure to wipe away the gel stain excesses as you work. In general, if you’re staining a workpiece with many grooves, facets, and angles, you need a more conventional stain.

Pine and maple, for example, tend to absorb stains indiscriminately. Therefore, a wood conditioner is used before applying Gel Stain to achieve even stain penetration.

If you’re not sure whether or not to use a gel stain on a project, try it on a tiny section of the surface you wish to stain and let it dry. To examine pigmentation and finishes, you may test using a liquid stain or paint. If you don’t like the results, sand the areas you utilized for these testing.