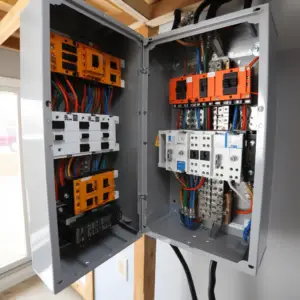

Many components are used during electrical installation, and each serves specific purposes. The entity that forms the essential part of the installation equation is the enclosures. Enclosures might appear to be the same and also serve similar functions. However, the truth is that they can’t.

It can be quite catastrophic if you swap one box for another unknowingly. Therefore, you must learn and be able to differentiate how you should handle each box.

Table of Contents

Pull Box Vs Junction Box

Let’s differentiate between a pull box and a junction box. Read on to know how they are used and the purposes they serve. Stay reading.

Junction Box

When electrical wires are spliced, tapped, or pulled together, a junction box serves as a container to keep them safe. To perform maintenance, electricians may easily reach the wires through the shields, which also guard against damage and unauthorized access.

Electrical fixture boxes are also referred to as “junction boxes”. The correct technical definition requires that wires in a junction box only connect to other wires and raceways. However, the term is frequently used to describe various types of electrical boxes that link wires to fixtures, including ceiling fans, light switches, and wall sockets.

Types of Junction Boxes

- Round Pan Junction Box

Round pan junction boxes are shallow containers with a maximum depth of approximately 34 inches. Most contractors install light fixtures and other small appliances throughout the wall or the ceiling, and the best idea is for them to use components weighing less than 22.6 kg.

It’s possible to install ceiling fans using specialized metallic junction pan boxes. However, the majority of models cannot support the extra weight.

- Octagon and Round Junction Box

Junction electrical boxes with the shape of an octagon or a circle provide a little more flexibility, depending on the container’s size.

This variety of junction boxes is frequently installed in ceilings or walls for lighting systems and ceiling fans that can only weigh a maximum of 22.6 Kg.

The best junction boxes for configurations that need more wiring space are round or octagon-shaped. If necessary, larger units can serve as more versatile junction boxes.

- Plastic and Metal Junction Boxes

Most electrical boxes are metal or plastic. Material selection depends on the project. A metal box is used to feed wires through a metal tube to a box. Metallic substance grounds tubes and wires better.

A junction box constructed of metal or plastic is used for non-metal connections. A cable clamp secures the wire to the box. Therefore, the connection is always secure.

How is the Sizing of the Junction Box Done?

The sizing of the junction box and the pull box is quite different. You can determine a junction box’s minimum and maximum capacity by looking at the guidelines instead of calculating them because they are standardized.

Pull Box

The container is used with conduits to make wire installation easy, hence the name pull box. Appliance molds make pull boxes.

Pull boxes are made from sheet metal, cast metal, or non-metallic materials. They allow long-range conductors to move without straining the wire’s insulation. Pull boxes fix lengthy wires at shorter intervals for angled and straight pulls.

Pull boxes don’t contain wire connections inside, despite their similar look to junction boxes. Only bent conductors feed into the raceway system.

Pull boxes are used in conduit lines when outlet bends exceed the National Electric Code’s maximum number.

The specific size of the pull box depends on the size and the number of conductors. In addition, the diameter and the quantity of the raceway also determined the size of the pull box.

Junction boxes and pull boxes used for the 4 AWG conductors and even greater ones should comply with the sizes recommended by article 314.28 of the NEC policies and regulations.

Types of Pull Box and How Sizes are Determined

Angle Pulls

Angle pulls require that the distance between each raceway entry within the box and the opposite wall of the box be equal to the sum of the following:

- The biggest racetrack is six times smaller than the trading dimension.

- All other raceway components in the row’s diameters were totalled up.

U-Pulls

The same formula is used to calculate the distance between the raceways’ entrance point and the opposing wall when conductors enter and depart from the same wall:

- The largest racetrack is six times smaller than the trading dimensions.

- All the other raceways in the same wall and row’s radius windage were combined.

It should be noted that each conductor’s entry and exit locations are counted separately.

-

Straight Pull

The conduit uses straight pulls as it enters and leaves the box from opposite sides. The depth of the pull box for a straight draw is determined by the dimensions of the largest conduit and the room needed for locknuts and bushings.

On the other hand, the draw box needs to be at least eight times the radius windage of the largest conduit.

-

Angle Pulls, U-Pull and Splices

Angle or U-pulls and conduit sections containing conductors 4 AWG or larger must be sized per NEC requirements.

-

Combination of Boxes with Straight and Angle Pulls

Whenever there are both angled and straight pulls in the same box, the calculations must be done using both sets of criteria and the largest dimensions.

Conclusion: Which Box?

Are you still having trouble distinguishing pull and junction boxes? Wires pulled directly through an enclosure and terminate downstream typically use pull boxes. Junction boxes are used to tap or splice conductors.

Electricians have learned from experience that shortchanging box sizes or quantities for a run is bad. Greater capacity makes pulling, splicing, tapping, and placing conductors easier in larger boxes.

No boxes should be placed where they’re unnecessary. Too many boxes increase conductor handling and splicing.

The NEC defines minimum specifications for straight or angle pulls with 4 AWG or larger wires per 370.28 to ensure enough working space in pull and junction boxes. Section 370.16 specifies enclosures for 6 AWG or smaller conductors. Remember that parameters determine box size.